As a manufacturer of food products for the general consumer and commercial use, we view the safety and security of the entire value chain as our primary concern and contribute to society by providing delicious products that respond to our customers’ requirements and trust in a stable and hygienic manner.

Food Safety Policy

- To comply with laws and ordinances, regulatory requirements, and customer requirements related to food safety and to observe predetermined ways of working to provide safe food products of high quality, we will build a food safety management system and use the Company’s management resources to continuously improve the effectiveness of the system.

- At the same time as promoting activities to increase the capabilities in food safety operations of the food safety teams and all employees, we will set annual targets for the improvement of the food safety system mechanisms. We will also introduce and implement mechanisms for regular evaluation, assessment, and review of the outcomes of those activities.

- We will strive to ensure that all employees are conscious of and understand the Food Safety Policy and the quality and food safety targets, and we will decide, communicate, implement, and thoroughly maintain responsibilities, authorities, and methods.

- We will strive for communication to ensure that we can always respond appropriately to customer needs and changes in the surrounding circumstances and pursue speedy decisions and action.

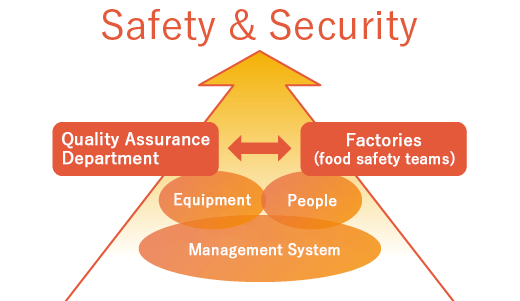

Quality Assurance System

Founded on safety and security, we aim to provide delicious food products that our customers can trust. To supply safer products in a stable manner, the factories’ food safety teams work together with the Quality Assurance Department to engage in continuous improvement activities by implementing the PDCA cycle based on the food safety management system.

We consider that, in addition to establishing the equipment for operating the food safety management system, people who will manage and operate the system are also important. We conduct a variety of education and guidance programs, including hygiene education for people involved in manufacturing, with a focus on the food safety teams, and engage in activities to raise awareness of food safety.

Food Safety Initiatives

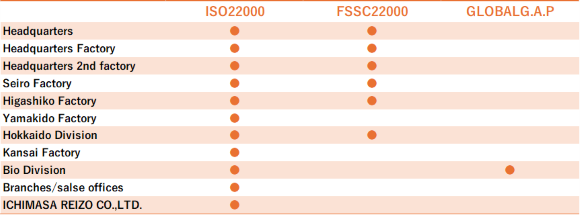

The Ichimasa Kamaboko Group manages its manufacturing processes based on the HACCP food hygiene management system. In addition, we have obtained certification for ISO 22000, the international standard for food safety management systems, for the whole company, and to pursue further food safety initiatives, our Headquarters, Headquarters Factory,Headquarters 2nd factory Seiro Factory, Higashi-ko Factory, and Hokkaido Factory obtained the FSSC 22000 certification.

・ISO 22000

International standard for food safety management systems. Reduces food safety risks based on HACCP food hygiene management methods and realizes the deployment of a safe food supply chain.

・FSSC 22000

International standard for food safety management systems designed for the practice of more certain food safety management, based on ISO 22000.

・GLOBALG.A.P

A farm assurance program in which the Global Food Safety Initiative (GFSI) certifies farming businesses that engage in sustainable production practices that are considerate of food safety, working environment, and environmental protection. The program is active in more than 120 countries around the world.

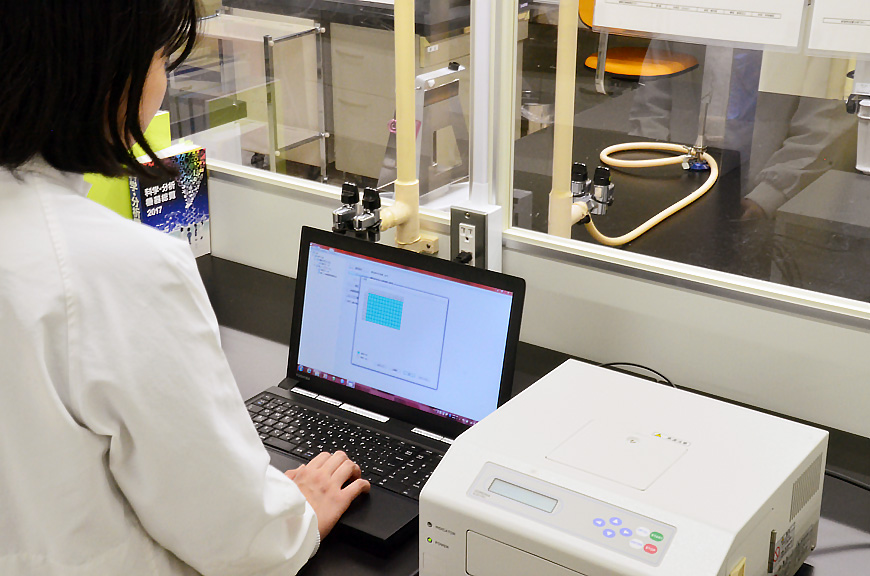

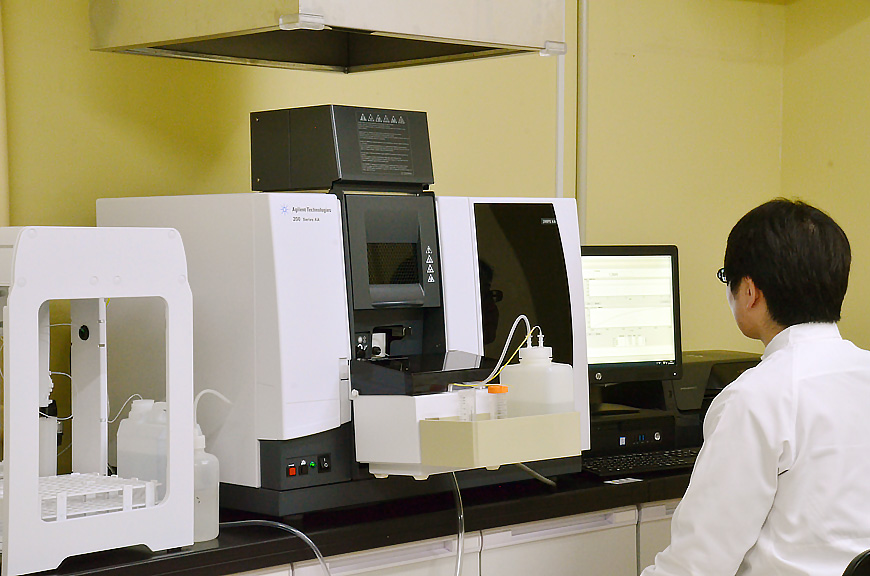

Initiatives for Certainty of Quality

In addition to final quality testing (microbiological testing, radioactivity testing, etc.) of manufactured products, we conduct tests of new ingredients in the development of new products, quality testing at the prototype stage, and shelf-life testing, to evaluate and verify the product before it is put on the market.

We conduct allergy labeling on our products that include the seven ingredients for which allergy labeling is mandatory (shrimp, crab, wheat, buckwheat, egg, dairy, peanuts) as well as the 21 allergens for which it is recommended (almond, abalone, squid, salmon roe, orange, cashews, kiwi fruit, beef, walnuts, sesame seeds, salmon, mackerel, soy, chicken, banana, pork, matsutake mushroom, peach, mountain yam, apple, gelatin).

We also respond in good faith to customer requests, while striving to achieve speedy, appropriate communication. We consider feedback to the factories about the contents of such requests and the verification of the effectiveness of subsequent improvements to be important functions.

Microbiological testing of manufactured products and ingredients used

Specified raw material testing (food allergen testing)

Component testing

of food products

Radioactivity testing of ingredients used, etc.

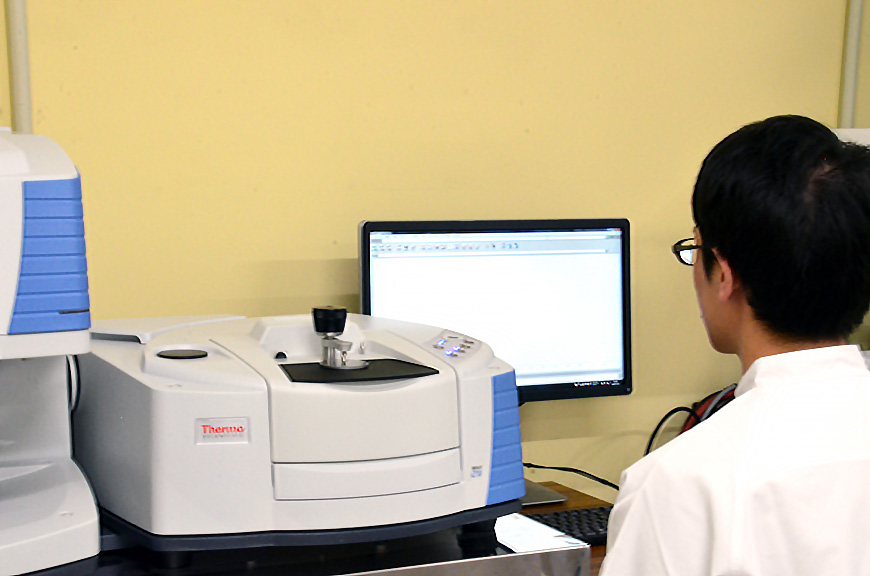

Material testing with infrared spectrophotometer

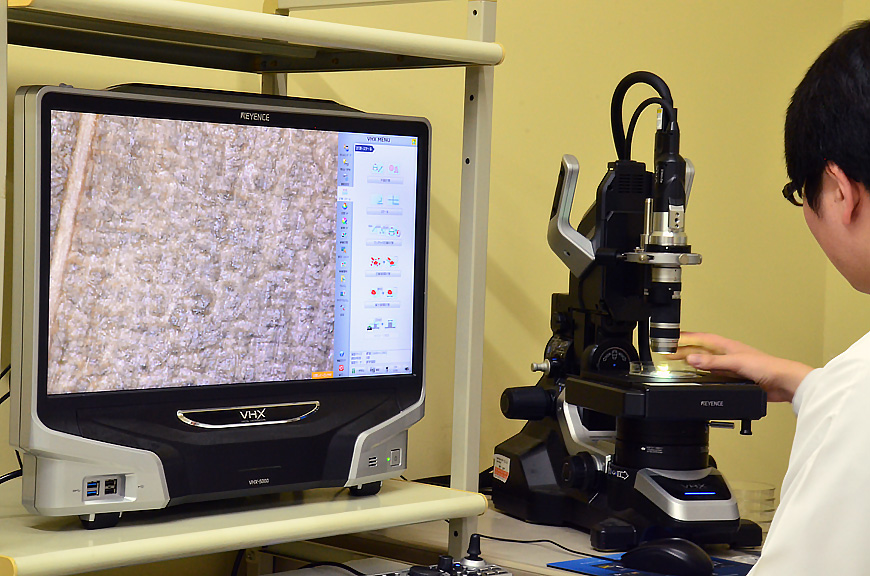

Analysis

with microscope