Efforts to Address Global Warming

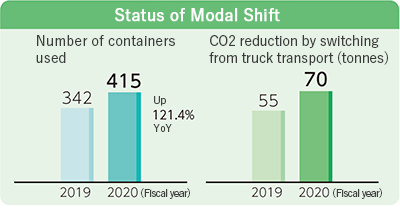

Modal shift

We use rail and marine transportation for some room temperature products like “Oden with Egg” in order to reduce our environmental impact, including CO2 emissions. We have reduced our CO2 emissions through a modal shift from truck to rail for transporting room temperature products to our five bases in Hokkaido, Aichi, Kyoto, Osaka, and Yamaguchi prefectures.

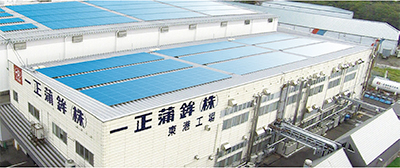

Additional introduction of solar panels

Solar power generation is conducted at two of our locations—Higashi-ko Factory and the Cultivation Center

Solar panels will also be installed at the No. 2 Plant of our Headquarters Factory, which is due for completion in the spring of 2023. In these ways, we will continue to promote the use of renewable energy.

Environmental consideration in packaging material

Use of eco-friendly packaging

We are working on switching to eco-friendly packaging to reduce CO2 emissions. Our “Oden with Egg” product features eco-friendly packaging made from recycled plastic bottles. This results in a roughly 3.7g (6.9%) reduction of CO2 per bag. We are also engaged in other efforts, such as using Eco-Tray® for Pure Fubuki. Eco-Tray® is made of recycled materials from used trays collected.

Convert product packages to biomass materials to save resources

With the aim of reducing our environmental impact, we have adopted biomass plastics, a low environmental-impact material made from renewable organic resources such as plants, for some packaging of our Salad Stick line of products. This initiative is contributing to the reduction of CO2 emissions. Further, from the perspective of reducing our plastic consumption, we have removed upper decorative portions of some product packages to make them more compact. This will allow us to reduce our plastic consumption by up to around 20% (compared with conventional packages).

Plastic Reduction Review Team

Plastic is thrown out and makes its way into the environment, causing a tremendous impact, not the least of which is the problem of marine debris. As such, we have established a “Declaration on Plastic Resource Recycling Action” and are working on the four issues shown on the right.

Click here for the Declaration on Plastic Resource Recycling Action

We have launched a Plastic Reduction Review Team consisting of persons in charge of purchasing, manufacturing, development, sales, and ESG to regularly share information in order to research curbing plastic consumption and using alternative materials.

Use of FSC-certified cardboard boxes

We hope to contribute to reducing illegal logging of timber and protecting limited forest resources by using FSC-certified cardboard boxes to package our products. FSC certification shows that the boxes are made from properly managed wood and are processed and distributed appropriately.

FSC-certified cardboard box

Effective use of resources

Extension of best-before dates

We are working to extend best-before dates to reduce food loss at stores and at home.

By making our “Mamekama” fish cakes exclusively from Alaska pollack, we have improved the supple texture and extended the best-before date by three days.

We also extended the best-before date of our “Kobashi Nama Chikuwa” fish sticks by three days by further enhancing the sanitary control at the factory.

The best-before dates of these products have been extended by three to eight days compared with similar products of our competitors.

We will continue working to contribute to reducing food loss from the standpoint of R&D and manufacturing control.

Mamekama

Best-before date: 20 days from the factory shipping date

Kobashi Nama Chikuwa

Best-before date: 15 days from the factory shipping date

Protecting marine resources

We are working on developing technology to extend product best-before dates to reduce the amount of food that is thrown away. The best-before date of our “Long-Keeping Unaru Oishisa Unajiro” imitation eel product was extended from 10 days to 17 days by making changes to the manufacturing process and packaging form. In May 2020, we succeeded in preserving the bold, rich flavor of the product without using eel extract so that it is now “eel free.” In this way, we are working to manage Japanese eel resources and pass on the broiled eel culture.